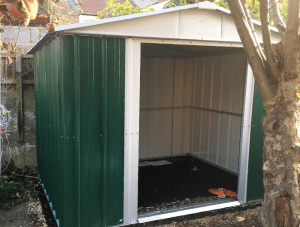

This case study comes from a past customer who has recently purchased himself a brand new, green metal shed for his garden and was in need of a suitable foundation.

Jump To:

| The Project | The Work | Conclusion |

The Project

Sindu had recently ordered himself an 8ft x 6ft green metal shed when the thought of foundations and bases crossed his mind. He needed a strong base to hold his shed and its contents so began searching the internet for the best solution. At first, he was toying with the idea of a concrete base, but soon realised it could end up costing him quite a lot to have it completed or would be very labour intensive to lay the base himself.

After further searching Sindu came across our website and began to browse our range of foundations, he read up on the fantastic benefits of our bases (can hold up to 420 tonnes per sqm, easy to install and permeable) and decided to order an 8ft x 6ft Plastic Shed Base the same day! As Sindu ordered before 12pm his base was dispatched the same day through DPD and arrived the next day!

The Work

Sindu received his base the next day in an easy to manage parcel for him to simply store until the day of installation.

Once the day of installation did arrive Sindu unpacked his base in the garden and set about installing his foundation. He began by preparing the ground and ensuring where the base would be installed was compacted. This is done to create a solid sub-base to ensure there is no movement when the base is stood on and also so any excess water can drain away naturally. With the ground prepared, he next laid and secured into the ground a sheet of Shed Base Membrane, membrane is used as a shield to stop any plants or weeds from growing up and through the base whilst ensuring any water can still drain away naturally.

Next, on top of the membrane Sindu began installing his 8ft x 6ft plastic shed base. He started in one corner and laid one panel at a time, simply connecting each piece together as he went along. Sindu told us how easy this was for him to complete.

Finally, with the base laid and secure, Sindu began filling the base with decorative gravel (around 8kg is needed per panel) . Once this was complete it was time to build his metal shed which as you can see he built from the ground upwards!

Conclusion

We’re sure you’ll agree that his shed and base looks great! Sindu was and still is very pleased with his brand new metal shed and fully recycled plastic base.

Sindu told us “Your shed base was great. It made my project far cheaper and easier.”

A huge thanks to Sindu for the images he sent us to create this case study, if you have any images or information to share with us or have any questions regarding our products then please do contact us.

How do you secure the shed to the base?

Hi Martin,

There are commonly ‘anchor points’ on the inside lip of the bottom of the shed. These can either be pinned through the grid and into the ground using something like a steel J-pin or U-pin or you can use heavy duty zip/cable ties to attach the shed to the base, filling the panels with gravel which acts as a ballast.

I am looking at a 10×8 shed on a plastic base like this, and want to build my shed right in the corner like this, but have seen online videos showing that you need to get behind the shed to put the screws in; How did you build yours without being able to get to the back?

Thanks

Hi Chris,

Thank you for your comment. In this blog, the customer fixed the shed panels together from the inside on parts of the shed where they could not get around the outside.

If you have any worries about erecting your shed it may be worth speaking to your shed supplier.

Hope this helps.