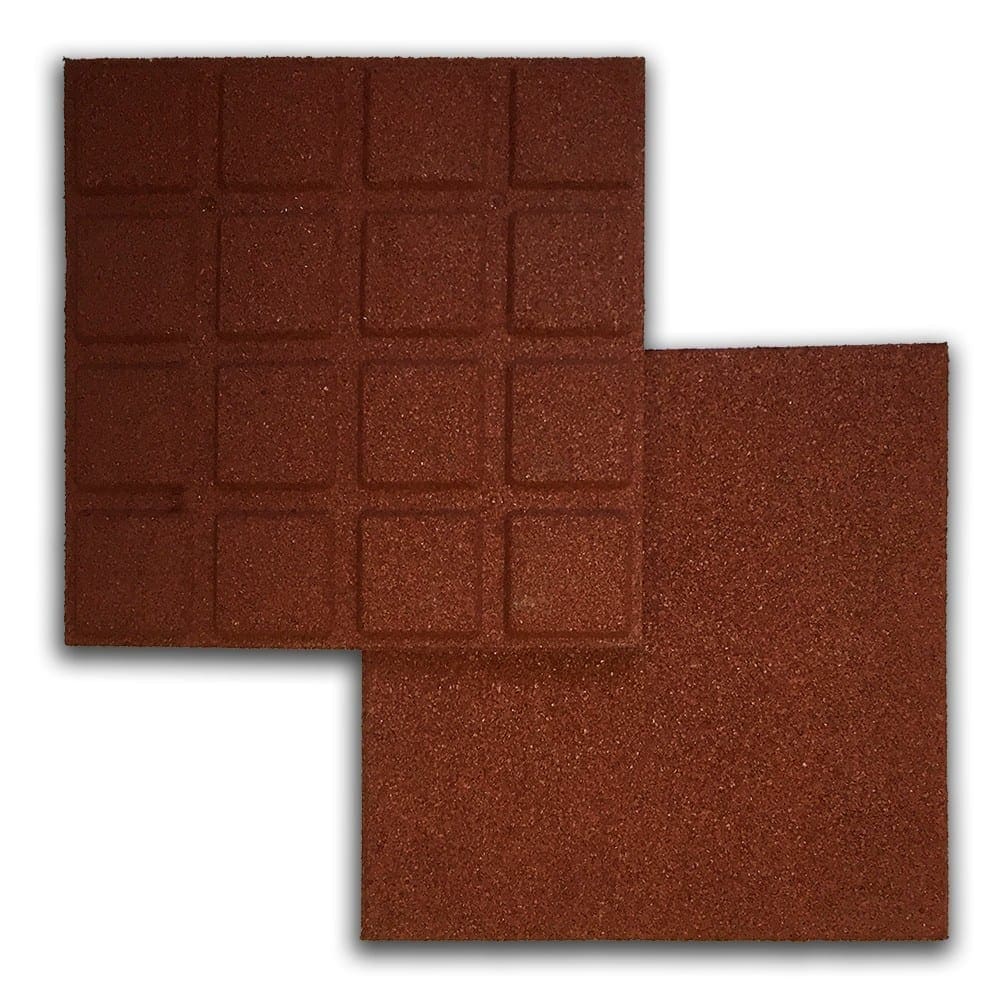

Rubber Tile – Red 4pk

Delivery only £10 per order to most UK areas

Shop now, pay later.

You may also like…

-

SAVE

29%

off RRP

Rubber Grass Mats 23mm Thick – 1.5x1m

Rated 4.95 out of 5£27.99Original price was: £27.99.£20.00Current price is: £20.00.Ready to ShipAdd to basket -

SAVE

34%

off RRP

Better Sports Utility Knife Lockable

£38.36Original price was: £38.36.£25.42Current price is: £25.42.Ready to ShipAdd to basket -

Connecting Peg Rubber Tiles – 100pk

£15.00Not AvailableOUT OF STOCK

Red Precast Rubber Tiles Perfect For Playgrounds, Gardens, Balconies and Garages

Our 100% recycled red rubber tiles are cost effective, attractive, strong, durable, non-slip, low maintenance, easy to install and weather resistant. They are the perfect product for use under low level childrens play equipment, as roof tiles, balcony flooring, gym flooring and much more!

- Quantity: Pack of 4 tiles

- Size: 500x500x30mm

- Colour: Red

- Tile weight: 6kg

- Material: Recycled Rubber

- Critical Fall Height: Up To 1m

- Colour options available: Red/Green/Black

- Expansion Tolerence: 10%

Delivery costs will be calculated at the checkout page

£47.00

Click here to ask a question

What are rubber play tiles suitable for?

They are suitable for low level children’s play equipment, as roof tiles, balcony flooring, gym flooring and more. Please contact us on live chat if you are unsure.

How do you cut or trim rubber tiles?

Rubber tiles are easily cut and trimmed with a stanley knife. You can see how in our How To Cut A Rubber Tile video.

Are the pegs included?

Yes, pegs are included to assist with installation but are these are not sold as interlocking mats.

Can I secure the rubber tiles to an existing solid surface?

Yes if used with the right installation and the use of a suitable rubber adhesive.

Have the tiles been certified?

Tested to BS EN 1177 standards, each tile has a critical fall height of one meter so it is suitable for low-level childs play.

Can I order a Rubber tile sample?

Yes, you can either buy one of our samples and pay for shipping, or buy one quantity of the item.

Can tiles be installed and left out all year round?

Yes, they are heavy-duty products and suitable to be left out all year round.

How do I clean the rubber tiles?

We recommend the use of warm, soapy water.

Can I be guaranteed the same colour all throughout my product?

Our products are new generation manufactured entirely from post-consumer recycled rubber; this means you may occasionally find very slightly different shades of colour.

Where can I find installation instructions?

Install guides can be found on the downloads tab. In addition, more information on installations can be found through our blogs.

How much is delivery?

The cost for delivery can be seen when you add your product to basket and at checkout.

How quick is shipping?

An expected delivery time will be displayed on the product page and clearly at checkout.

About Our Red Rubber Tiles

Made from 100% recycled rubber our rubber tiles are a versatile, non-slip, weatherproof, strong, durable, low maintenance and cost effective flooring solution for so many applications including play areas, roofing, balcony flooring and so much more. Despite its toughness, the tiles still keep natural drainage routes open to allow air, water and essential nutrients to reach the ground below which is not always the case with other rubber flooring products. Used in a number of ways from creating playground flooring to being used on roofs, our tiles are the ideal product for so many projects thanks to their many benefits. Once installed you may need to maintain should they get dirty by simply cleaning the tiles with warm soapy water. As we also stock other coloured tiles, you can either create one solid colour area or make decorative or patterned areas by using the different coloured tiles.

Due to the typical manufacturing tolerances and the expansion and contraction of rubber under temperature fluctuations, we cannot guarantee that all holes will be aligned and some tiles may require additional bonding or drilling to create perfect alignment. These tiles may be supplied with 8 pins per tile to assist with installation but are not sold as interlocking, therefore any tiles with alignment issues will not be deemed to be faulty.

What Can The Rubber Tiles Be Used For?

Our fully recycled rubber tiles are versatile rubber flooring solutions that can used in all weathers to create durable yet soft under foot rubber surfaces for a multitude of applications. Being easy to install using rubber adhesive, our tiles are a simple yet effective solution for so many applications. You can create vibrant or natural looking, low maintenance areas by using one colour or multiple coloured tiles for solid or patterned surfaces. Thanks to the tiles many benefits they can be used in ways we may have never even thought of which is what makes them such an exciting product. Below are just a few examples of how our Rubber Tiles have been commonly used and continue to be used:

Playground Flooring

Our rubber tiles can be used in both low-level commercial playgrounds and domestic play areas under smaller play equipment to create a stable, non-slip and low maintenance safety flooring. Tested to BS EN 1177 standards, each tile has a critical fall height of one meter so is suitable for low level child’s play. Available in Red, Green or Black you can create attractive, stimulating and vibrant ground whilst increasing the safety of the play equipment. As well as being used next to play and climbing equipment, some customers have also used the tiles in sensory gardens, outside exploring areas and so much more. The tiles create a soft, safe and decorative flooring to encourage children to continue their development safely outdoors whilst giving you piece of mind that there is a safe flooring where your children are playing.

Roof Tiles

The strength, durability, easy maintenance and weather resistance of our rubber tiles make them an ideal product for creating hard standing and attractive rubber surfaces for single pitch or flat roofs. A rubber roof is easy to create using our tiles by simply laying a waterproof substrate before using rubber adhesive to secure rubber tiles to the substrate. Once installed, you will have an attractive, noise reducing, thermally insulating and anti-slip roofing solution that will last for years to come.

Balcony Flooring

Our rubber tiles are a fantastic and easy to install product which is great for creating a balcony, terrace or veranda flooring that will carry benefits that other products are not able to produce. The previously mentioned benefits will allow you to have a soft surface so you are able to walk barefoot, a weather resistant floor which will not rot if exposed to water or be affected by extreme hot and cold temperatures and a secure covering that will not separate when walked on.

How Do You Install Rubber Tiles?

Interlocking Method (For use on a granular base):

- Prepare your granular sub-base of soil or sand etc. You must ensure that your hardcore is level and well compacted by using a vibration plate.

- Measure and mark out your area where the tiles will be installed. Install an edging system around the perimeter of where the tiles will be laid to prevent outer edges moving (this can be made from concrete, plastic, timber or rubber).

- On top of the prepared granular sub-base, start in one corner and lay the tiles one row at a time, connecting and butting together any neighbouring tiles using the interlocking pegs. Push the interlocking pegs half way into the pre-drilled holes of a tile before pushing the next tile onto two of the pegs sticking out and ensure they are pressed tightly together with no gaps visible. Repeat this process of laying one row at a time (either straight or brick-bond for more flexibility) and connecting as you go along until the entire area has been filled.

- If desired, polyurethane adhesive can be used in the joints of each tile to ensure total integrity and ensure the tiles are fixed sufficiently to prevent migration of materials.

Non-Interlocking Method (For use on a solid base):

- Prepare your sub-base, concrete or tarmac. Ensure your concrete is seal, fully cured, crack and gap free. Or ensure that your tarmac is hard, flat, dry, fully cured over 30 days and is free of all impurities.

- Measure and mark out your area where the tiles will be installed. Install an edging system around the perimeter of where the tiles will be laid to prevent outer edges moving (this can be made from concrete, plastic, timber or rubber).

- Using an appropriate polyurethane adhesive, apply 4 rows of the adhesive to under side of the tile in a 3mm bead. Secure the tile in place and ensure there is a 3-4mm joint between each tile that can be filled with sand or another fine-grade, porous medium which allows for tile expansion over time. Repeat this process until the area has been filled and the tiles

are butting with the edging installed earlier.

If you require more information on our rubber tiles or would like some advice on whether or not our rubber tiles would be suitable your project, please do not hesitate to get in touch today. Leave us a message or live chat to a member of our staff now.

You may also like…

-

SAVE

29%

off RRP

Rubber Grass Mats 23mm Thick – 1.5x1m

Rated 4.95 out of 5£27.99Original price was: £27.99.£20.00Current price is: £20.00.Ready to ShipAdd to basket -

SAVE

34%

off RRP

Better Sports Utility Knife Lockable

£38.36Original price was: £38.36.£25.42Current price is: £25.42.Ready to ShipAdd to basket -

Connecting Peg Rubber Tiles – 100pk

£15.00Not AvailableOUT OF STOCK